When one of the UK’s leading retailers wanted to create ‘one of their big five’ food halls at a large out of town shopping centre in Essex, Space Engineering Services were engaged to supply and install the refrigeration systems.

Based on a consultant detailed design and client led specification – keeping to high standards, Space installed and commissioned two direct expansion R744 (CO2) dual temperature transcritical ‘Booster’ systems. These were to serve and satisfy the remote sales floor display cases, chill room, and cold room requirements.

The 2no dual temperature space packs were manufactured by our Pack Build facility and supplied in dual walk-in housing. Positioned with anti-vibration mountings, the pack frames accommodated compressors, pressure vessels, filters, oil management system, pipe work, valves and control panels. The housing was also fitted with access doors, ventilation grilles and louvers, lighting, emergency lighting, and power socket outlets.

Bitzer compressors were selected and featured critical factors such as energy efficient design, noise and vibration, space and accessibility, heat dissipation and weigh. They were also equipped with the following:

The Kelvion gas coolers were located on the roof of the building, in close proximity to the packs. These were designed to an outside ambient of +35°C with a consideration for when the air-on temperature may exceed the ambient temperature. When selecting the gas coolers, the lowest refrigerant operating charge was considered.

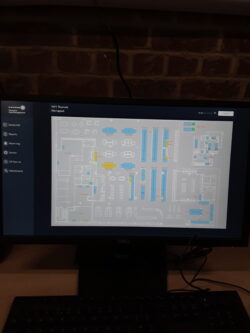

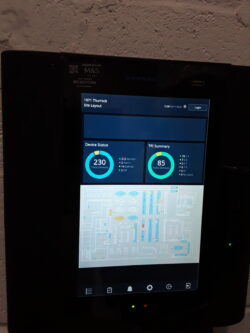

Each refrigeration packaged plant was connected to a common TCP IP based communications network, centrally connected to the clients business critical network. Both Primary and Back up plant control utilises a “superpack” RDM pack controller. Primary control and backup control are both be capable of providing full plant operation without dependency on the other. The RDM Monitors suction and discharge temperatures, refrigerant leak detection, and output from manufacturers leak detection / ventilation system. The RDM pack controller is configured to fuzzy logic for controlling the compressor staging and variable speed output.

Our customer was featured on an ITV X series, with this high profile store being the focus of the second episode, just before Christmas, so there was no room for error during the programme of works. Space successfully commissioned and handed over to the client, allowing a happy end to the ITV program!

As part of a £1.8m investment, one of the UK's leading food processors engaged with Space to design, supply and install refrigeration equipment for a...

Read more

As part of a competitive tender process, Space Engineering successfully secured the multi phased upgrade works for an existing M&S retail site in Fosse Park....

Read more

Our valued customer needed to replace their high GWP refrigeration equipment for their picking freezer. As Space Engineering understand our clients needs, factoring both CAPEX...

Read moreWe’d love to hear from you. Please enter your details in the form below and we will get back to you.

We take your privacy seriously. We will keep your data safe and we won’t pass it on to any third parties.

Please see our privacy policy for more details.